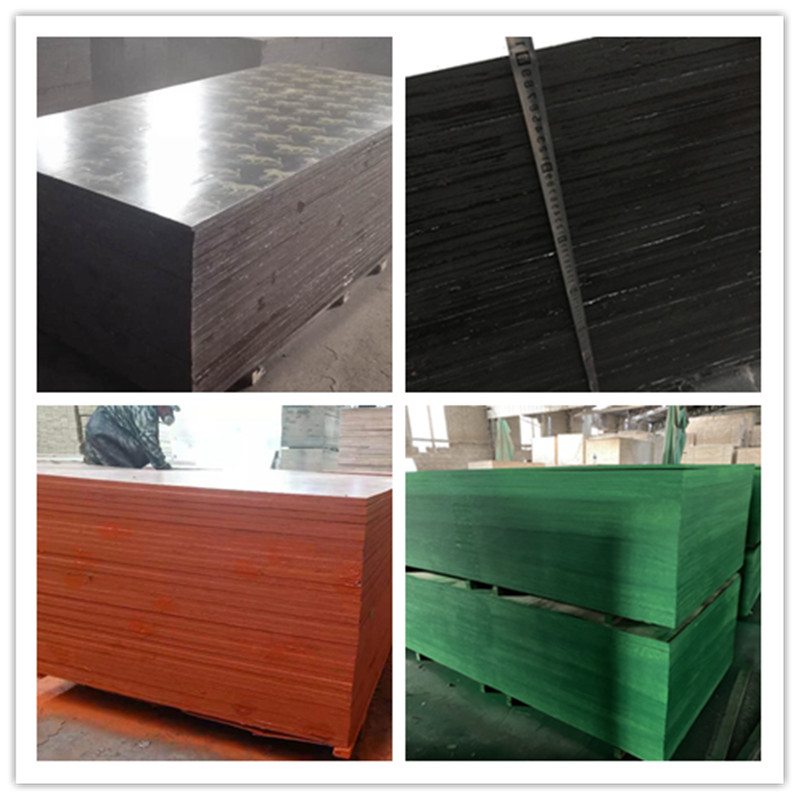

Film Faced Plywood/Marine Plywood /Construction Formwork Board

Specification

| Item: | Film Faced Plywood/Marine Plywood /Construction Formwork Board |

| Size Options: | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm |

| Core Options: | Poplar,hardwood,birch,combine |

| Thickness: | 6mm,9mm,12mm,15mm,18mm,20mm,21mm,25mm |

| Film Options: | black, brown, red, yellow, green, orange |

| Length(width) tolerance: | +/-0.2mm |

| Thickness tolerance: | +/-0.5mm |

| Edge: | Sealed with waterproof paint |

| Glue: | MR, WBP(Phenolic), Melamine |

| Moisture: | 6-14% |

| Packing: | By bulk, loose packin, or by standard pallet packing |

| Minimum order quantity: | 1*20GP |

| Usage: | Usded for construction, building house, flooring, shopping mall… |

| Payment term: | TT or L/C at sight |

| Delivery time: | Within 15 days after getting down payment |

Introduction

Film Faced Plywood is the special plywood with one or two sides coated with wearable and water-proof film which protect the core from moisture, water, weather and extend the plywood’s life. With the above advantages, what is film-faced plywood use?

Some of the film faced plywood uses

1. Construction industry

Film-faced plywood uses for making formwork in construction because of its increased stability and resistance to moisture, ultraviolet radiation, and corrosive chemicals. The film layer and acrylic varnished edges make it more durable and less able to distort when used outdoors in harsh weather and adverse conditions.

Film-faced plywood is recommended for shuttering boxes as these are used to soothe and restrict wet concrete as it dries. If the shuttering box is made from film-faced plywood then it can last long even in the sunlight. Hence, it can be used several times before being replaced. This saves money as well as keeps things safe.

2. Industrial development

In some cases, film-faced plywood seems like marine plywood. It uses good quality hardwood, waterproof glue and tends to be light, firm, and virtually free of defects. Film-faced plywood is also known as “Water-boiled Plywood” as it can be boiled in water for up to 20-60 hours without lamination. These qualities are what make this plywood a popular choice for boat building, shipbuilding, and boat, and ship parts.

In the construction and maintenance of dams, people use film-faced plywood to create forming-level molding boards and girder molding boards. These boards can face up with the fast-flowing water due to their water resistance. The boards can vary in thickness i.e. 12mm, 15mm, 18mm, 21mm, 24mm, and 27mm…

3. Film faced plywood can be used for shelves and furniture

Currently, industrial plywood is considered to be a material with many high advantages of technical properties, so it is very popular for use in furniture making. Industrial plywood helps to overcome the situation of warping, not being termite with many different styles and wood grain for you to choose from depending on the purpose of use.

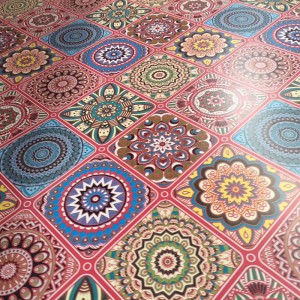

In addition, the film outside also brings natural wood grain plywood products from color to texture, products from bright colors to luxurious dark colors for you to choose from. In particular, thanks to the film veneer layer, helps to protect the color of the furniture.

4.Is widely used in Wall paneling,inner home

decoration,furniture,cabinet,cupboard,wardrobe, inner home designing wall and ceiling linings in caravans and relocatable buildings, temporary construction decoration, movie or TV scene decoration, and other decoration.