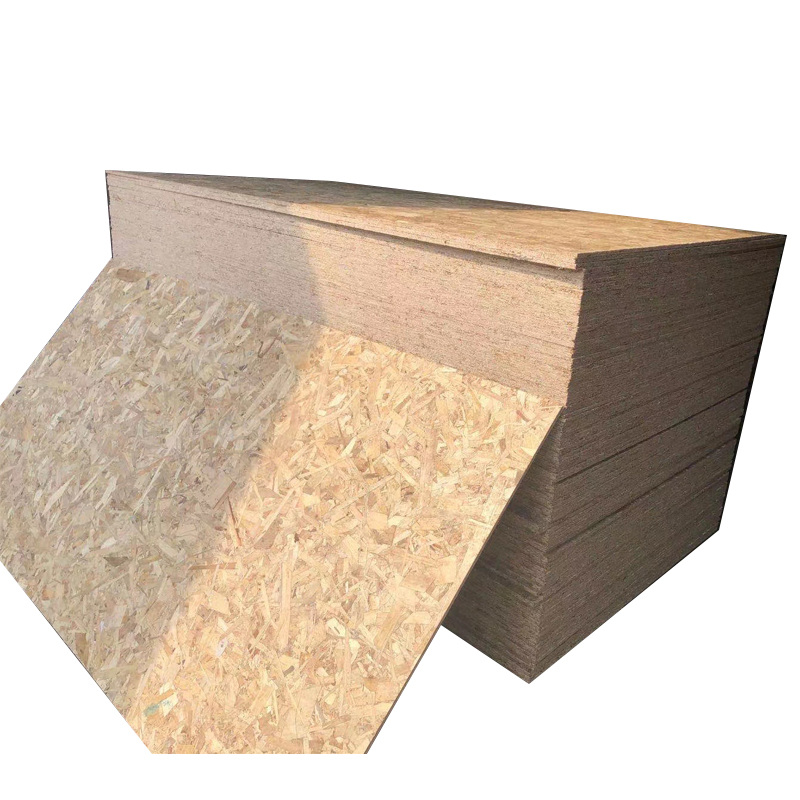

Oriented strand board (OSB)

Specification

| Product Name+B2:C20 | Oriented strand board (OSB) |

| Material | Poplar, Pine, Combi, Hardwood |

| Glue | WBP / Phenolic /E0 /E1/E2 |

| Size | 1220x2440,1250x2500 or accept customization |

| Thickness | 6-45mm (9.5mm,11.1mm,12mm,15mm,18mm) or as requests |

| MOQ | 1*20Feet |

| Delivery Time | 15-25 Days |

| Thickness Tolerance | Thickness:+/ -0.2mm |

| Size Tolerance | Length &Width:+/-2mm |

| Usage | Roof decking, furniture, packing, hoarding, signboards and portable building, constructional insulation board, |

| Density | 600-700KG/CBM |

| Production Advantages: | 1. Tight construction and high strength; |

| 2. Minimum twisting, delamination or warping; | |

| 3. Water proof, consistent when exposed in the natural or wet environment; | |

| 4. Low formaldehyde emission; | |

| 5. Good nailing strength, easy to be sawn, nailed, drilled, grooved, planed, filed or polished; | |

| 6. Good heat and sound resistant, easy to be coated; | |

| 7. Note the OSB 3 is for use on flat roof situtaions, a far better product than standard chipboard or particleboard. | |

| Payment | T/T or L/C at sight |

Introduction

Melamine faced boards, sometimes called Conti-board or melamine chipboard, is a versatile type of board with many different applications and uses from bedroom furniture like wardrobes to kitchen cabinets. They play a crucial role in the modern-day building and construction. Apart from the boards being attractive, they are durable and easy to clean.

The task of installing melamine faced boards is not as hard as people may tend to perceive and many home and business owners are going for them as opposed to wooden boards. Many people are, however, not sure where they can use melamine boards in construction. Here is a look at some of the places that are worth trying for that elegant and unique appearance. Whether in your home or business, always choose the best installer for the boards as they are fragile during installation if not handled with care.

Kitchens

One of the most common places where melamine boards are used is the kitchen area when constructing frames and kitchen cabinets. The decision to use these boards in the kitchen is because there is much spillage of fluids and other solids in the kitchen area which needs constant cleaning. Using melamine on frames and cabinets makes cleaning easy and fast while keeping the kitchen area always dry. The use of melamine boards also eliminates the infestation of mould which thrives on wet surfaces. Once these have been completed, there are a wide variety of options for doors and accessories.

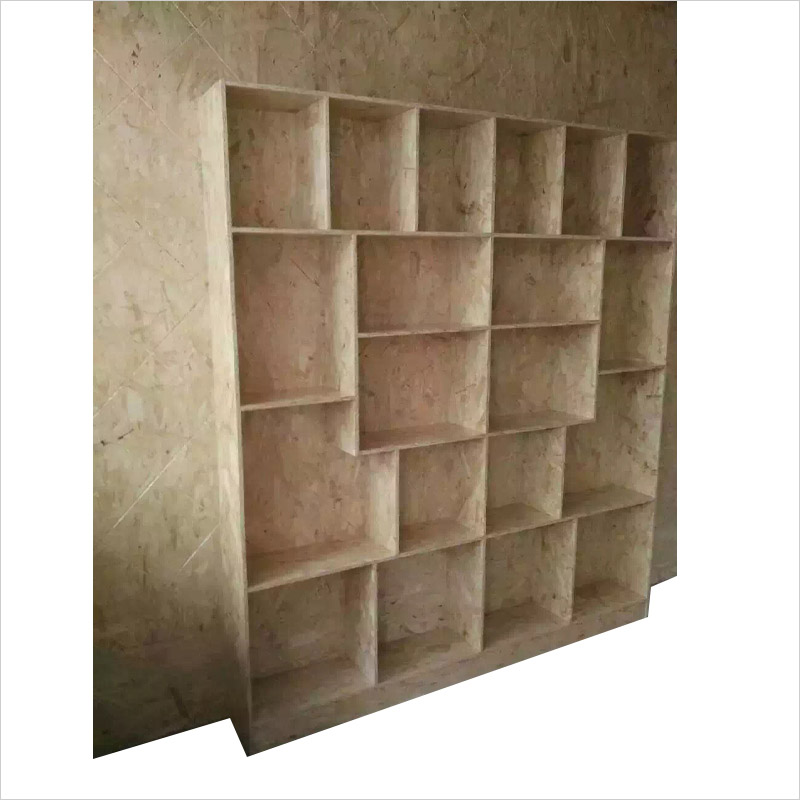

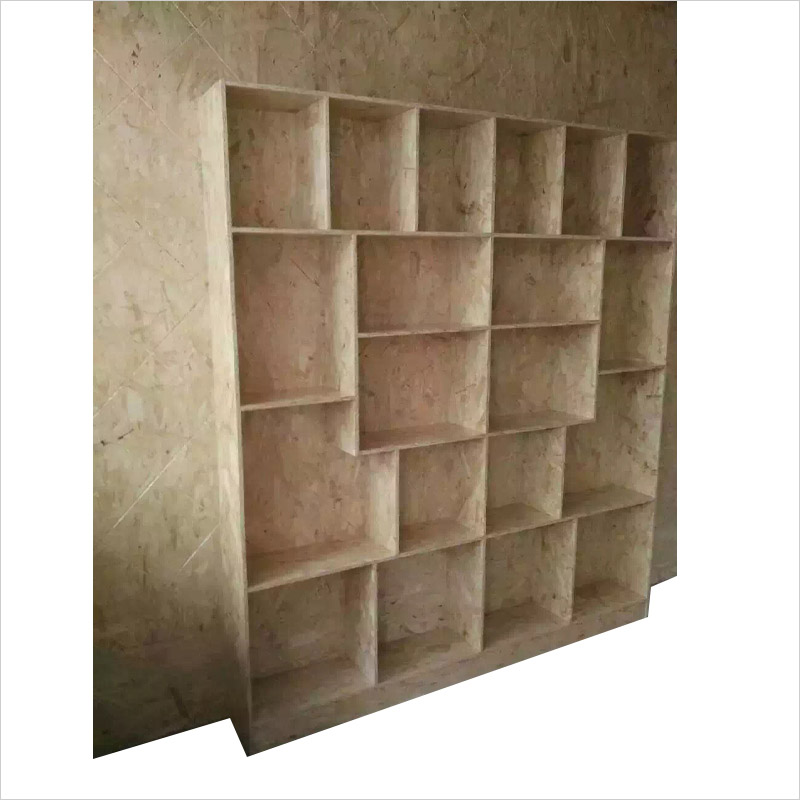

Shelves

Since melamine boards are tool friendly, it is a simple matter to cut them to any size and they can also be faced with any one of a huge range of colours. To help with matching other interior design choices, it is also possible to use edging tape in complementary or contrasting colours.

Melamine boards come in different colours which make it one of the favourite decorative materials for interior designers. The use of melamine boards on shelves allows a mixture of various colours to be used and bring out an appealing look of the interior. Some of these shelves may be installed in offices or other working areas like libraries to give a bright outlook and boost the mood of the room.

In the Bedroom

Melamine boards are perfectly suited for the construction of bespoke cabinets, wardrobes and other bedroom furniture. This means that creating custom bedroom furniture for a fraction of the cost of buying a new set can be easily accomplished for a small fraction of the cost.

Service Counters

Melamine boards have become a common sight on surfaces which serve as tables in various places. These areas include butcheries, bar counters and hotels where the surface is always in use. Unlike timber and plywood units, melamine boards do not need any treatment or many coats of finish to make them water resistant or smooth through sanding. Counters which are exposed to dragging of objects and spillage are best made with melamine boards since there is very little damage that can occur on the surfaces owing, to the smooth surface of melamine boards. Melamine boards do not need constant care of painting and smoothening as they can retain their initial appearance for years

Whiteboards

Melamine boards are paint-resistant products which makes them a primary component in the manufacture of whiteboards. These whiteboards have become common in schools and boardroom meetings due to their ease of use which is in contrast to the use of chalkboards. Melamine boards can be cut and moulded easily to any size and shape according to the size of whiteboards needed.

Flooring

People who are working on a constrained budget during construction may opt to go for melamine boards for the floor rather than concrete tiles which are expensive and hard to keep clean. Melamine boards need a simple mopping to remain dry and dust free, making them some of the best materials to use in busy places like hotels and banking halls.