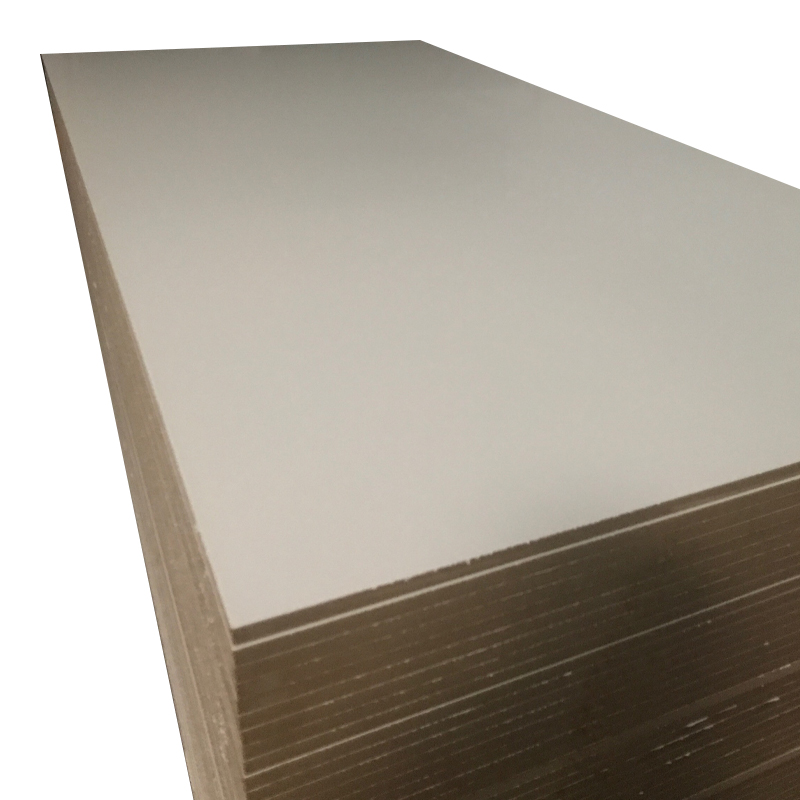

Plain MDF HDP Melamine MDF Paper overlay MDF plywood

Specification

| Product Name | Plain MDF/Raw MDF/Medium Density Fiberboard/MR/HMR/Moisture Resistance MDF |

| Size | 1220X2440mm1525x2440mm,, 1220x2745mm, 1830x2745mm, 915x2135mm or as client’s request |

| Thickness | 1.0~30mm |

| Thickness Tolerance | +/-0.2mm:for 6.0mm up thickness |

| Core Material | Wood fiber (poplar, pine or combi) |

| Glue | E0, E1 or E2 |

| Grade | A grade or as client’s request |

| Density | 650~750kg/m3 (thickness>6mm), 750~850kg/m3 (thickness≤6mm) |

| Usage & Performance | Melamine MDF is widely used for furniture, cabinet, wooden door, interior decoration and wood flooring. With good properties, suchas, easy polishing and painting, easy fabricability, heat resistant, anti-static, long-lasting and no seasonal effect. |

| Packing | Looseing packing,Standard export pallet packing |

| MOQ | 1x20FCL |

| Supply Ability | 50000cbm/month |

| Payment Terms | T/T or L/C at sight |

| Delivery Time | Within 15 days after receiving deposit or original L/C |

Packing

MDF is a kind of man-made board made of wood or plant fiber through mechanical separation and chemical treatment, mixed with adhesive and waterproof agent, and then formed at high temperature and high pressure. It is an ideal man-made board for making furniture. The structure of MDF is more uniform than that of natural wood, which also avoids the problems of decay and moth. At the same time, it has small expansion and shrinkage and is easy to process. Due to the flat surface of MDF, it is easy to paste various finishes, which can make the finished furniture more beautiful. It is superior to Particleboard in bending strength and impact strength.

Because the fiber structure of the board is uniform and the bonding strength between fibers is high, its static bending strength, plane tensile strength and elastic modulus are better than those of particleboard. The screw holding force, moisture absorption, water absorption and thickness expansion rate are low.